The West Indies covers many different islands. Some of them require ISPM 15 certification for wood packaging while others do not show up on the list of countries that require it. Cuba, Jamaica and Trinidad/Tobago are three countries that are listed as requiring ISPM 15 certification. Consider having your wood packaging ISPM 15 certified and labeled as such if you are shipping to the West Indies just to be safe.

There are several different sets of rules for Western Red Cedar. The one that applies to the wood you have will depend in part on what country the wood came from and also on the grade.

If the cedar came from Canada, then the rules that cover it may be those published by the National Lumber Grades Authority (NLGA) in Vancouver, British Columbia. Those rules are available on their website at www.nlga.ca. You will find the rules on their “publications” page.

If the cedar came from the U.S., the rules could be those published by the West Coast Lumber Inspection Bureau (WCLIB) in Portland, Oregon, or rules published by the Western Wood Products Association (WWPA) in Portland, Oregon. The WCLIB rules are available in the Publications section of our website. You will want to look at Standard Grading Rules No. 17. The WWPA rules are available on their website at www.wwpa.org. You will find them under their “publications” page.

The Western Red Cedar Lumber Association (WRCLA) also publishes some proprietary rules for Western Red Cedar siding. Their website (www.realcedar.com) is useful because you can go to the type of siding you have and they cross-reference the various rules mentioned above that pertain to different grades of cedar siding, including their own proprietary rules when appropriate.

Finally, it is also possible (but not likely) that the wood was produced under our rules, the Export R List. While they are not yet up on our website at this time, if you find that the wood you have was produced under an R List rule, let us know and we will email you the relevant rules.

The basic wane allowed in Select Structural J&P is 1/4 width and 1/4 thickness full length – you can have both. When it comes to the maximum wane allowed you can also have both in the same cross-section. The rule states only “…provided that wane not exceed ½ the thickness or 1/3 the width for up to 1/4 the length.” Maximum wane in width and thickness in the same cross-section would still meet that criteria.

There is no specific requirement concerning grade stamp placement. Grade stamps can be located anywhere on the piece. Placing them away from the end allows pieces to be trimmed in the field and still retain the stamp, but there is no rule that governs specifically where it has to be located along the length of the piece. Grade stamps must contain certain elements and need to be legible. Another thing to keep in mind is that any other additional information that is not part of the grade stamp must be at least 6″ away from the grade stamp. For example, if you are printing a proprietary grade name like “Premium” on the piece, that would need to be at least 6″ away from the grade stamp. The same holds true for grader IDs and production date stamps.

The mark you describe indicates that the pallet complies with ISPM 15, an international standard that was developed to help reduce the spread of wood-borne pests in solid wood packaging materials. Much more information on ISPM 15 can be found on our website under ISPM 15 Wood Packaging. MX indicates the pallet was treated by a registered facility in Mexico with identification number 899. HT indicates it was heat treated.

I would imagine that the reason people have advised using pallets with the HT mark is that pallets with that mark have been heated in a heating chamber or kiln to a specific temperature to kill most bugs and pathogens. KD refers to the moisture content of the wood, so a piece of wood that has KD usually means it has been dried to 19% or less moisture content. If kept in that condition, that would reduce the chance of mold. DB refers to debarked but we don’t use it in this country and it is typically not used anymore.

We are trying to sell our home in Poughkeepsie, NY. When My husband and I bought it, we were told that it was a Sears Kit Home; however, we have not been able to authenticate it. Some people have even said that it is not a Sears model and may very well not be a kit home.

We are trying to sell our home in Poughkeepsie, NY. When My husband and I bought it, we were told that it was a Sears Kit Home; however, we have not been able to authenticate it. Some people have even said that it is not a Sears model and may very well not be a kit home.

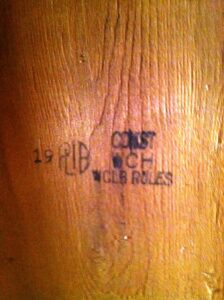

The attached photos are of wood beams and boards from the unfinished basement. Is it possible that the home is a Pacific Ready Cut Kit Home, or is there another reason why a house on the East Coast would have been built in the 1920s using wood inspected on the West Coast?

Could you please help us find out exactly how this house was built, if it’s a Pacific Ready Cut or another kit home, or if it is a kit home at all?

Unfortunately, we cannot tell you whether your house is a Sears kit house or not. However, we can confirm that the pictures of the stamps are Pacific Lumber Inspection Bureau (PLIB) grade stamps and we did indeed have certified graders at mills in the 1920s. The WCH is an abbreviation used during that time period and stands for the species of wood, in this case, West Coast Hemlock. The number on the stamps is the Mill ID number (the mill that produced the lumber). STAN and CONST indicate the grade of the wood – Standard or Construction. WCLB RULES indicates that it was graded using the grading rules published by West Coast Lumber Inspection Bureau (WCLIB) at that time.

Unfortunately, we cannot tell you whether your house is a Sears kit house or not. However, we can confirm that the pictures of the stamps are Pacific Lumber Inspection Bureau (PLIB) grade stamps and we did indeed have certified graders at mills in the 1920s. The WCH is an abbreviation used during that time period and stands for the species of wood, in this case, West Coast Hemlock. The number on the stamps is the Mill ID number (the mill that produced the lumber). STAN and CONST indicate the grade of the wood – Standard or Construction. WCLB RULES indicates that it was graded using the grading rules published by West Coast Lumber Inspection Bureau (WCLIB) at that time.

As to your question about why would a house on the East Coast be built using wood inspected on the West Coast, the answer is lumber from the West Coast has been shipped across the country, and in fact all over the world, for well over 100 years so it is not unusual to find lumber used in construction on the East Coast with our stamp on it.

That’s a great question and one that is often misunderstood. The short answer is no. Kiln-dried lumber does not necessarily meet the requirements for heat treating. Or put another way, not all kiln-dried (KD) lumber is heat-treated (HT), and not all heat-treated lumber is kiln-dried.

The term kiln-dried, or KD, refers to lumber that has been dried in a kiln to a moisture content that does not exceed a specified maximum level. The keyword here is dried and note there is no mention of temperature. The term heat-treated, or HT, refers to lumber that has been heated to a specific core temperature (56℃) for a minimum of 30 minutes – note there is no mention of drying or moisture content.

So you can have KD lumber that has been properly dried using a low-temperature drying schedule that does not meet the temperature requirements for heat treating. Likewise, you can heat lumber so that it meets the HT requirements without drying it at all. In fact, it is not uncommon to produce HT lumber that is unseasoned (green).

If you are buying KD lumber or any dry lumber for that matter, and it needs to be heat-treated, make sure you specify HT when you place your order. That way the producer can label it properly with an HT mark or issue an HT certificate. It may not be possible to certify material as HT after it has been shipped. Similarly, if your HT lumber needs to be dry, you’ll need to specify that as well.