Structural Glued Laminated Timber (glulam) technology was originally developed in Europe and was first introduced in North America in 1934. As markets became more familiar with glulam and its advantages over alternatives, demand increased and manufacturing expanded to meet that increasing demand. In 2018, North American demand for glulam was estimated to be 444,300 cubic meters, or about 188 million board feet, and for good reasons:

Wood products in general have a number of sustainable characteristics:

- They come from a renewable resource—Thanks to reforestation and replanting harvested areas, the amount of forested acres and the standing timber inventories on that acreage across North America are both greater than they were 1900.

- Wood products have low embodied energy compared to alternatives—the bulk of the energy needed comes from the sun while the trees are growing.

- Compared with alternatives, manufacturing wood products consumes low amounts of water and produces low levels of air and water pollution.

- Wood products store atmospheric carbon at a rate of nearly a ton per cubic meter of solid wood, making them an important tool in the fight against climate change.

- Wood products are reusable and recyclable and biodegradable. In many cases, after they’ve served their useful life, they can be burned to produce more energy than was required to make them in the first place.

Glulam extends those benefits in several ways:

- Glulam technology optimizes wood resources by using higher strength lumber in areas where stresses are highest and lower grades in other laminations where strength requirements are lower.

- Glulam technology uses dimensional lumber derived from smaller-diameter second and third-growth forests to make large structural timbers that previously could only come from old growth.

- Glulam allows for custom sizes that meet exact specifications, significantly reducing jobsite waste.

- The versatility of glulam allows it to be used in applications where structural steel or concrete might otherwise be used, helping to reduce the severe environmental impacts associated with those non-renewable products.

Long, clear spans and majestic soaring arches are no problem for this versatile structural material. The manufacturing process allows for a wide range of straight, tapered or curved shapes that can be joined together to accomplish many engineering feats.

Glulam trusses, beams and arches are used to efficiently accomplish the clear spans required for expansive open spaces such as gymnasiums, ecclesiastical structures, indoor pools, sports and concert venues, auditoriums, and even domed arenas.

Pressure-treated glulam and glulam made with naturally-durable wood species are well-suited for creating beautiful bridges and waterfront structures such as piers and wharfs. The product has been used for countless pedestrian, forest, highway and railway bridges throughout the world.

AITC’s quality control and inspection service is provided by Pacific Lumber Inspection Bureau as a part of PLIB’s Certification and Inspection Services. The program comprises three basic elements:

- PLIB licenses qualified laminators whose personnel, procedures, and facilities have been audited for compliance with the current edition of ANSI A190.1.

- Each licensee agrees to accept responsibility for maintaining a quality control system that complies with the current editions of ANSI A190.1, AITC Standards, and AITC Quality Control Systems Manual.

- PLIB employs a nationwide team of qualified inspectors who conducts frequent, unannounced audits and verification of laminators’ in-plant quality control systems, procedures, and production.

This Quality Control program provides assurance to architects, engineers, contractors, and building inspection authorities that AITC/PLIB members’ structural glued laminated timber (glulam) products will perform in use according to the design standards established for each product type.

AITC standards are recognized by all major building codes in the United States. Standards and technical notes developed by AITC provide guidance to building officials and industry professionals in the design and use of glued laminated timber.

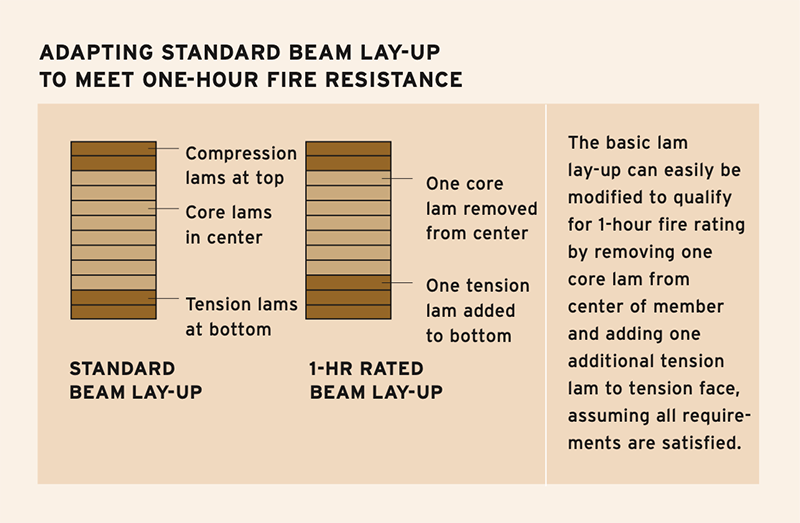

Fire resistance refers to the amount of time a structural member can support its load before collapsing, a critical measurement when it comes to life and safety concerns in the built environment. As wood burns, it forms a char layer that provides protection to the remaining wood. This makes heavy timber materials such as glulam and CLT much more fire-resistant than the dimension lumber used in light-framing. Steel, on the other hand, is non-combustible but it’s also not fire-resistant. Unprotected steel weakens dramatically as its temperature climbs above 450° Fahrenheit, retaining only 10% of its strength at about 1380°F. The average building fire temperatures range from 1290°F to 1650°F.

Fire resistance refers to the amount of time a structural member can support its load before collapsing, a critical measurement when it comes to life and safety concerns in the built environment. As wood burns, it forms a char layer that provides protection to the remaining wood. This makes heavy timber materials such as glulam and CLT much more fire-resistant than the dimension lumber used in light-framing. Steel, on the other hand, is non-combustible but it’s also not fire-resistant. Unprotected steel weakens dramatically as its temperature climbs above 450° Fahrenheit, retaining only 10% of its strength at about 1380°F. The average building fire temperatures range from 1290°F to 1650°F.

The standard test for measuring fire resistance is the ASTM International, Inc. (ASTM) Test Method E-119. Ratings of assemblies (including beams, walls, and floors) are determined by test procedures that approximate actual fire conditions. Results of ASTM fire tests for building assemblies, sponsored jointly by the American Wood Council (AWC) and the American Institute of Timber Construction, enable designers to calculate specific fire ratings for glulam members. Calculations are based on a consideration of member size, degree of fire exposure, and loads on the member. For more details see:

As is often the case, simply comparing the base costs of various structural building materials will not provide a complete picture of the cost-effectiveness of glulam. While not seen in a materials take-off comparison, a number of glulam attributes will provide overall cost savings nonetheless.

- Because glulam is fire-resistant in its own right and aesthetically pleasing when exposed, it can serve as both the structure and the finish material in many applications. There is no need to use fire-proofing chemicals like those used to protect steel columns and girders, nor is there a need to cover the wood with gypsum or drywall and then paint.

- Accurate manufacturing reduces the need for on-site fabrication, minimizing waste and labor costs during installation. Equally important, glulam timbers are readily adapted to design changes and minor adjustments during construction. Because glulam may be easily modified in the field to fit existing conditions, renovation projects are also simplified.

- The laminating process and use of kiln-dried lumber to manufacture glued laminated timbers minimize wood’s natural propensity to check, twist, warp, and shrink in-service. Installations remain dimensionally stable and beautiful over time, virtually eliminating the need for expensive repairs and callbacks.

- Frequently used for spans exceeding 100 feet with no intermediate posts or columns, glulam construction is visually and structurally adaptable and often reduces the overall cost of a project.

- Significant overall construction cost savings can be achieved when building design teams provide detailed specifications to glulam suppliers who can then use those details to provide ready-to-install structural members to job sites. This results in a significant saving in both time of construction and reduction of crew size required to erect a structure.

The laminating process allows timbers to be produced in a variety of shapes from straight beams to graceful, curved arches. This architectural adaptability allows glulam to extend the enduring qualities of wood into applications as varied as individual designers’ imaginations.

While often delivered to job site prefabricated to exacting tolerances, individual glulams also are easily modified and fabricated on-site making them visually and structurally adaptable.

Common uses in residential construction include ridge beams, garage door headers, door and window headers, and columns. High strength and stiffness make glulam beams ideal for long-span girders and beams needed for commercial construction. Glulam arch systems and trusses further increase the aesthetic and structural possibilities, including timber bridges, sports arenas, places of worship, and many other applications.

The size of structural glued laminated timber members is limited only by transportation and handling constraints. Widths up to 103/4 inches are manufactured using single laminations across the width. Wider sizes are manufactured using two or more laminations across the width of the member. Typical depths range from 51/2 inches up to several feet. Standard sizes are described in AITC 113, Standard for Dimensions of Structural Glued Laminated Timber.

Not to be confused with manufacturing (the actual bonding together of laminations), fabrication is the process of cutting, drilling or otherwise modifying structural glulam for the purpose of construction. It may also include installation of connectors, simplifying the jobsite construction process to essentially the assembly of a kit. Fabrication often involves the use of computer aided design (CAD) software and sophisticated machinery capable of cutting and drilling to extremely tight tolerances. Pre-fabricated glulam members can significantly reduce installation time and costs.

Many glulam manufacturers offer in-house fabrication capabilities. Others make use of independent fabricators, a growing niche with the advent and popularity of mass timber construction. Regardless of how fabrication is provided, the most important factor is that it be done correctly to avoid mistakes. Improperly fabricated glulam delivered to a jobsite can result in costly construction delays while waiting for replacement product to arrive.

Such mishaps can be minimized by utilizing fabricators who have been certified through the AITC Timber Fabricators Program, designed to ensure conformance to the International Building Code (IBC). Section 1704.2 of the IBC requires that special inspectors be present during the fabrication of structural load-bearing members and assemblies, including wood fabrications (section 1704.6). Section 1704.2.2 offers an exception when a fabricator has a fabrication program in place. AITC’s program is designed to fulfill this requirement allowing an AITC Certified Fabricator to avoid the costly and time-consuming requirement for special inspectors. Moreover there currently are no accredited wood fabrication special inspectors in the United States, making the fulfillment of this requirement impossible without some sort of approved fabrication program like AITC’s.

Becoming certified

- View the AITC Certification Process Outline.

- Download the Application.

- Please contact us for fee information or with any questions.

You can also download the sample manual, complete with fill-in-the-blank procedures. For more information on glulam fabrication, see:

AITC 115 – Standard for Fabricated Structural Glued Laminated Timber Components and Assemblies

Smaller glulam members are easily maneuvered manually. Larger timbers and custom configurations can be installed with mobile construction equipment. Conventional hand and power tools are typically used for modifications and connections.

Standard connection details reduce mistakes and allow for rapid installation. AITC 104 Typical Construction Details provides additional guidance for detailing glulam timbers. Off-site fabrication of custom laminated timbers further reduces installation time.

AITC manufacturing plants are located throughout the United States. See our member directory for a current list. Straight beams in common sizes, often referred to as “stock beams,” are mass produced and readily available at most building material and lumber distribution centers. Custom beams are available in infinite sizes, both curved and straight (or cambered for longer straight spans) and are typically cut-to-length and prefabricated to arrive at the job site ready for immediate installation. These may be obtained directly from the manufacturer or a local representative.